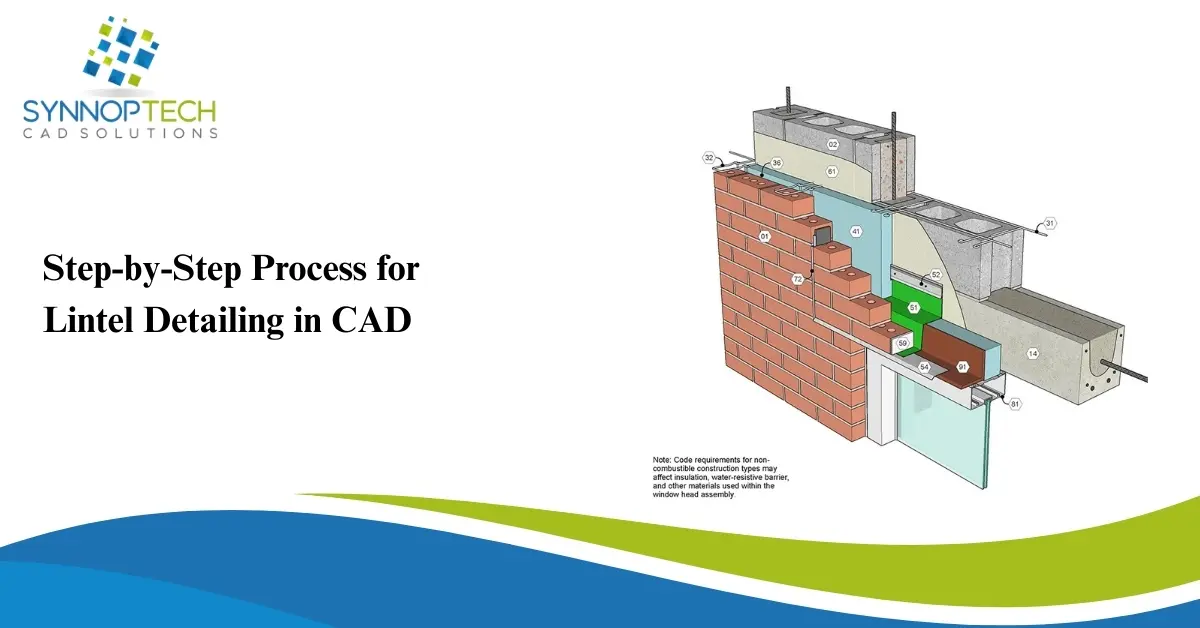

Accurate lintel detailing plays a crucial role in construction drawings. A well-prepared CAD lintel detail ensures proper load transfer, prevents site confusion, and helps avoid costly errors during construction. Whether you are a beginner learning CAD detailing or an experienced draftsman refining your workflow, following a structured approach is essential.

This guide walks you through the complete step-by-step process of lintel detailing in CAD, from reviewing drawings to final quality checks.

Why Lintel Detailing Is Important in CAD Drawings

Lintels support masonry or concrete above openings such as doors and windows. Incorrect lintel details can lead to structural cracks, poor load distribution, or construction delays.

CAD drawings act as the bridge between design and execution. Clear lintel detailing helps engineers, contractors, and site teams understand exactly how the lintel should be constructed.

Understanding Lintel Detailing Requirements

Before opening your CAD software, it’s important to understand what needs to be shown in a lintel detail.

Lintel drawings typically include:

- Lintel type and material

- Dimensions and bearing length

- Reinforcement details

- Concrete grade and steel specifications

- Notes aligned with structural design

Coordination between architectural drawings and structural plans is essential at this stage.

Tools and Software Used for Lintel Detailing

Most lintel detailing is done using AutoCAD or similar CAD software. Key tools commonly used include:

- Layers for structural elements

- Blocks for repeated lintel details

- Dimensioning and annotation tools

- Standard text styles and scales

Using predefined templates helps maintain consistency across drawings.

Step 1: Review Architectural Drawings Carefully

Start by studying the architectural layout. Identify:

- Door and window openings

- Wall thicknesses

- Span lengths

- Floor levels and lintel levels

This step ensures your lintel details align correctly with the building layout.

Step 2: Select the Appropriate Lintel Type

Based on structural design and span length, select the correct lintel type:

- RCC lintels for most residential and commercial buildings

- Steel lintels for heavy loads or wide openings

- Precast lintels for faster site execution

Always refer to structural notes or calculations before finalizing the lintel type.

Step 3: Set Up the CAD Drawing Properly

Before drawing, prepare your CAD environment:

- Set units and scale correctly

- Create layers for lintel outlines, reinforcement, dimensions, and text

- Use standard line types and colors

This setup keeps the drawing clean and easy to understand.

Step 4: Draw the Lintel Section and Elevation

Begin by drawing the lintel outline above the opening:

- Show the lintel position clearly

- Draw cross-sections to represent depth and width

- Align the lintel correctly with wall geometry

For beginners, it’s best to start with simple sections before moving to detailed elevations.

Step 5: Add Reinforcement Details

Reinforcement is a critical part of lintel detailing:

- Draw main bars and distribution bars clearly

- Indicate bar diameter and spacing

- Show concrete cover on all sides

Advanced users may create reinforcement blocks to speed up repetitive detailing.

Step 6: Dimensioning and Annotation

Accurate dimensions make the drawing construction-ready:

- Indicate lintel length, depth, and width

- Show bearing length on both sides

- Add clear material and reinforcement notes

Use consistent text sizes and avoid clutter.

Step 7: Add Construction Notes and Specifications

Include essential construction information such as:

- Concrete grade

- Steel grade

- Reference to relevant design standards

- Execution instructions for site teams

These notes reduce confusion during construction.

Step 8: Cross-Check with Structural Drawings

Before finalizing, verify:

- Alignment with beams and slabs

- No clashes with electrical or plumbing services

- Consistency with structural framing plans

Coordination at this stage prevents site-level errors.

Step 9: Perform Final Quality Checks

A thorough review ensures professional output:

- Check dimensions and reinforcement labels

- Verify layer usage and visibility

- Ensure drawing readability at print scale

Advanced users may follow an internal checklist for quality assurance.

Common Mistakes to Avoid in Lintel CAD Detailing

- Missing or unclear reinforcement details

- Incorrect lintel size or bearing length

- Poor coordination with architectural drawings

- Overcrowded annotations

Avoiding these mistakes improves both accuracy and credibility.

Summary: Lintel detailing in CAD is a small but vital part of structural drawings. A step-by-step approach helps beginners build confidence while allowing advanced users to maintain precision and efficiency.

When done correctly, clear lintel details ensure smoother construction, fewer site issues, and better structural performance. Mastering this process is an important skill for every CAD technician, engineer, and draftsman.