In construction and structural engineering, precision remains a top priority. Reinforcement detailing—where rebars are positioned, stacked, bent, and fused within the structure—claims the singular focus of any concrete structure. For most projects, this used to be a 2D drafter’s work; however, over time, the complexity of structures necessitated a departure from flat 2D visuals.

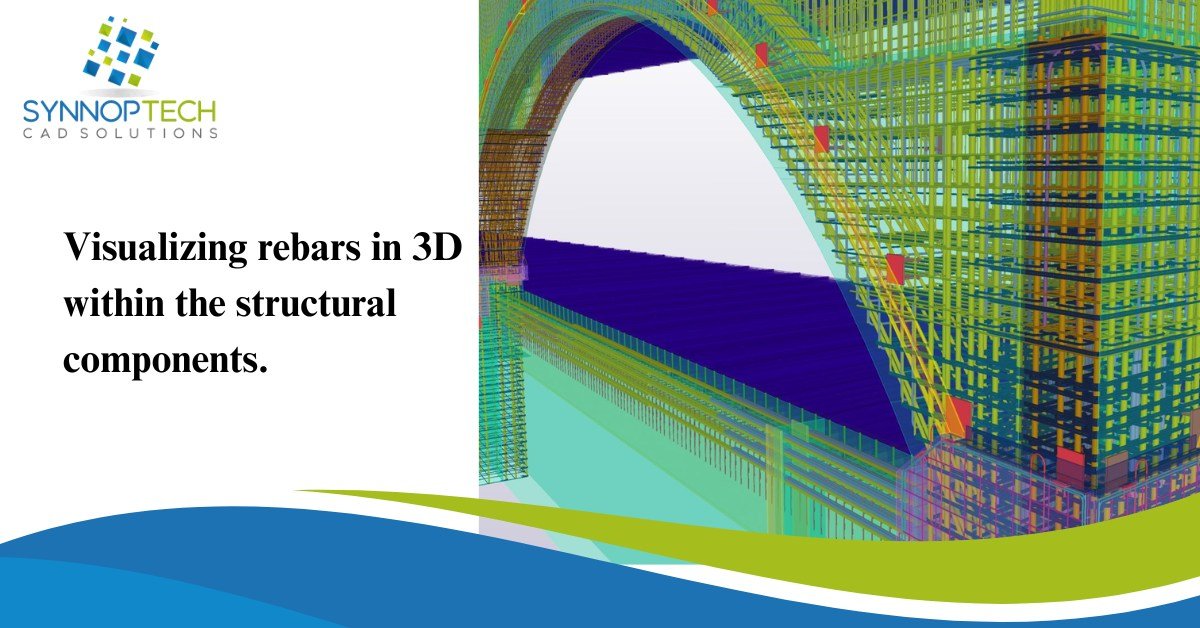

3D rebar visualization is the paradigm shift, as it allows engineers, construction workers, and architects to interact with rebars within structural members such as slabs, beams, walls, and columns in a scaled digital environment.

The construction life cycle, from design to actual work, is changing on all fronts due to 3D visualization of rebars.

What Is Rebar 3D Visualization?

3D visualization of rebars means inserting rebars volumetrically into columns, beams, walls, and any structural elements within three-dimensional space. Instead of trying to decipher abstract 2D lines and annotations, stakeholders can observe with precision—spacing, cover, lap lengths, bends, hooks, and even intersections—how the rebars are within a column or a beam.

- Autodesk Revit

- Tekla Structures

- Allplan Engineering

- Advance Steel

These software not only allow for detailed rebar modeling but also for inter-system conflict checks through BIM (Building Information Modeling) collaboration.

Importance of Rebar 3D Visualization

1. Enhanced Comprehension of Design

The 3D perspective makes complex reinforcement designs more interpretable for engineers and designers. For example, stirrups and bent bars in dense columns can be inspected in 3D to verify no conflict exists.

2. Collision Conflict Resolution

2D architectural representations can easily hide overlap events with rebars and other building systems like Mechanical, Electrical, and Plumbing (MEP) systems. 3D representation eradicates this problem. Problems can be solved visually during the design stage, which brings great time and cost savings.

3. Construction Work Accuracy Improvement

Team members on site gain accurate directions compared to 2D schematics. Instead of interpreting 2D rebar plans, construction teams now have the visuals, which leads to increased accuracy and improved construction execution.

4. Overestimated material savings

Sufficiently detailed visuals enable accurate estimates of the bar bending schedule (BBS) drawing and cutting lists, therefore reducing material wastage and cost optimization.

5. Improved Communication with Stakeholders

Explaining reinforcement strategies to clients, consultants, or stakeholders with minimal technical backgrounds is easier with 3D models. This speeds up the approval process.

Applications Across Structural Elements

Beams

Designers can better visualize and check the anchorage lengths, spacing, stirrup positioning, and the termination or continuation of rebars across spans by 3D viewing rebars within the beams.

Slabs

3D models for flat slabs or waffle slabs depict the reinforcement mesh as well as the layering of the bars, which interface with openings or drop panels.

Walls

3D visualization for shear or retaining walls offers insight into the proper alignment of horizontal and vertical bars for anchorage and checks for service interference.

Columns

For highly congested columns, 3D views enhance the planning process for vertical bars, ties, and starter bars, thus improving the buildability of the structure.

Integrated BIM Workflows

The advantages of 3D rebar visualization are enhanced even further when integrated with other BIM tools.

Models of reinforcement detailing sync with the construction schedule, activity timeline, and cost, offering greater control.

Collaboration with other disciplines, such as architectural and MEP, is seamless and interference-free.

The accuracy of as-built documentation and facility management after construction improves significantly.

Would you like to see how 3D rebar detailing aligns with a BIM workflow? Follow this link to read our post:

👉 👉 Explore Our Blog on 3D Reinforcement Modeling: Construction Work with Smart Technology

Real-World Example: From Model to Site

Let’s examine a bridge pier with a complex rebar cage. In 2D drawings, maintaining a proper distance between the longitudinal and transverse bars along with embedded conduits becomes very demanding.

But in a 3D model:

– Areas of congestion can be spotted immediately.

– Alterations can be executed within the model.

– Updated models refresh fabrication drawings and bending schedules.

– Crews execute work using 3D digital models as visual guides.

The ability to visualize structural components and associated rebar cages in 3D models is rapidly becoming an industry standard. The ability to reduce errors and clashes while improving communications, standard compliance, and 3D rebar detailing enables teams to build smarter, faster, and more accurately.

Adopting 3D models for rebar detailing strengthens project integrity and illustrates the industry’s commitment to digital innovation, ensuring adaptability.

Reach Out for Expert Assistance in 3D Rebar Detailing.

At SynnopTech CAD, we specialize in rebar detailing, BIM integration, and 3D rebar modeling for reinforced concrete structures. Contact us today to discuss how we can assist you in your upcoming project.