With advancements in construction and civil engineering, the design and visualization processes of reinforcements have changed for the better. The tedious practice of depicting the intricate arrangement of steel bars embedded within concrete structures on 2D sketches is long gone. The construction industry is now increasingly leaning towards 3D modeling of reinforcements. This method is more beneficial for the engineering, architecture, and construction teams because of its unparalleled precision and productivity. It provides great enhancements to every phase of a project, from the beginning design all the way to the execution at the site.

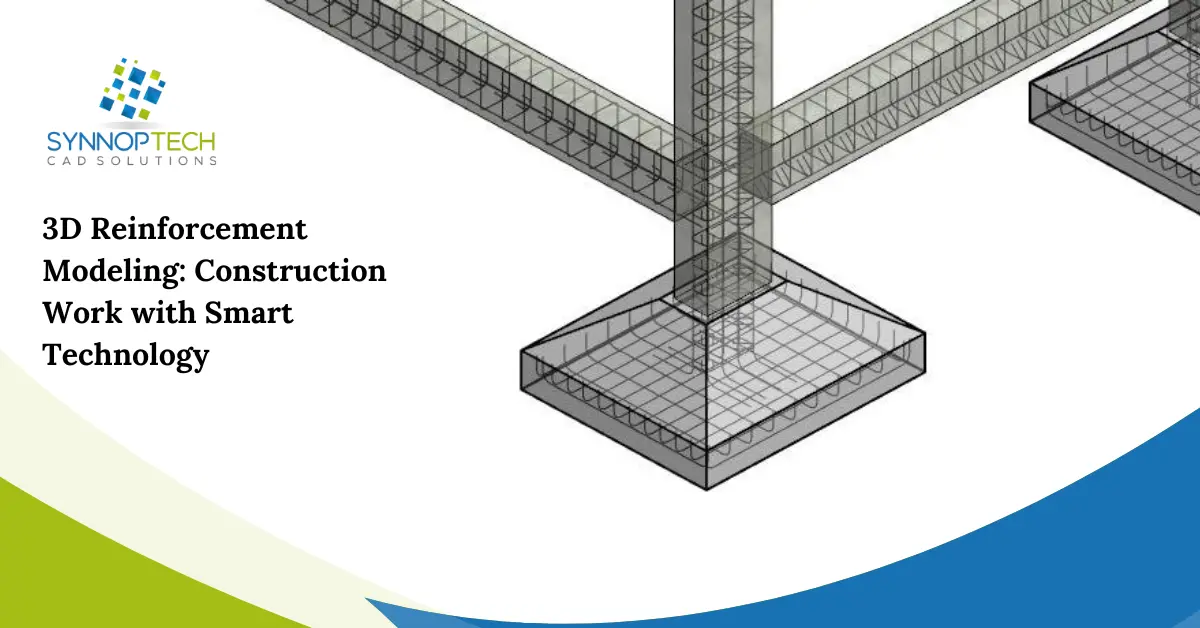

All stakeholders can see how rebars are integrated within columns, beams, slabs, walls, and foundations. Engineers can build digital models of the structure’s internal skeleton, which allows for early detection of potential problems, minimizes errors, and enhances interdisciplinary collaboration. This article discusses in depth the efficiency of 3D reinforcement modeling.

3D reinforcement modeling has been revolutionary for the construction industry. The previously utilized 2D drawings served their purpose, but they do not accurately describe complex structures. Different elements, such as coverings, spacings, intersections, and clearances, are hard to depict on flat drawings. On the other hand, 3D modeling displays the entirety of the picture, highlighting how the rebars interact with other structural components, mitigating clashes, and maintaining compliance with the design standards. With this realistic view, both the designers and contractors understand the structure better and assist in thorough comprehension prior to construction.

Improved precision and detail with 3D Reinforcement Modeling

As previously mentioned, precision matters, especially during reinforcement. A single tiny error in rebar positioning can have adverse impacts on a structure’s strength as well as stability. The risks mentioned above are greatly diminished with 3D modeling. Engineers can now accurately determine the size, shape, position, and quantity of reinforcement bars and visually assess each component in three-dimensional space.

3D models improve onsite accuracy since there is no room for assumptions. The construction teams have a clear view of how rebars are supposed to be bent, placed, and overlapped. Better compliance leads to improved performance and reduced chances of errors stemming from incorrect interpretations.

Reducing error and clash detection time

One of the features of 3D reinforcement modeling is automatic clash detection. Conflicts are bound to occur when multiple systems—electrical conduits, plumbing pipes, and steel reinforcements—all occupy the same space. While these clashes may be overlooked in 2D drawings, they are very obvious in 3D models.

Your team is able to avoid potential conflicts and resource wastage by resolving issues during the design phase instead of offline. This enhances efficiency during the construction stage and leads to reduced delays and smoother workflows.

Modifications and Updates Are Easier

Everyone involved in a construction project knows that design alterations are a standard practice. The traditional method of updating reinforcement drawings tends to draw a lot of time and resources due to its repetitive nature. In the case of 3D modeling, however, the opposite is true—changes are easier to implement.

The good news is that intelligent updates are possible with most 3D modeling software. Changes to models also affect parts connected to the scope of work, so interdependencies are taken care of automatically. All perspectives also maintain consistency and coherence across plans, sections, elevations, and schedules, leading to the elimination of handling ghost dimensions.

Elevated Collaboration and Communication

Contractors, architects, clients, and structural engineers are the main participants in any construction project. Proper communication improves outcomes and is key to success. Complex ideas are made easy to share and explain through 3D reinforcement models.

Instead of showing the detailed technical drawings, engineers can showcase a 3D model that clearly displays all reinforcements and their interactions. Even non-technical stakeholders find it easier to understand the provided information, which allows everyone to give approval fast. Coordination improves, as does the reduction in miscommunication.

Integration with BIM and Tools Used in the Construction Industry

The 3D reinforcement modeling process is frequently done in conjunction with a BIM workflow. When the 3D modeling for reinforcement is done with BIM tools, then the model is integrated with the rest of the infrastructure project’s digital twin.

The use of 3D modeling within BIM provides precise estimating, planning, logistics, and overall schedule control. The construction phase data helps in improved planning, collaboration with other trades, and enhanced facility management post-project completion.

BBS Accuracy in Bar Bending and Reinforcement Bars

A bar bending schedule (BBS) is critical for precision when cutting and shaping reinforcement bars. With 3D modeling, the rebar bending schedule can be automated, which lowers human error and ensures accuracy of the amount and shape of bars sent to the site.

Accurate fabrication leads to reduced waste and labor costs. On-site installation becomes streamlined, while off-site work allows for better tower planning and scheduling around material delivery, aiding with project timelines.

Tools That Support 3D Reinforcement Modeling

Currently, there are numerous tools that support 3D reinforcement modeling, such as

- Autodesk Revit—The software has sophisticated tools for structural modeling and designing reinforcement within a BIM alongside an environment.

- Tekla Structures—well-known for its thorough rebar detailing, along with fabrication-ready outputs.

- Advance Concrete/Advance Steel—CAD-based instruments that assist with 3D detailing and rebar modeling.

- Allplan Engineering— Used more broadly in Europe, it provides reliable BIM-integrated 3D rebar modeling.

Aside from modeling, these platforms assist with scheduling, documentation, and collaboration-related tasks.

Building Smarter with 3D Reinforcement Modeling

The 3D modeling of reinforcements is revolutionizing the designing, planning, and execution of construction projects. This technology enables smarter, safer, and more efficient building practices by increasing accuracy and collaboration while reducing errors.

3D reinforcement modeling aids in visualizing intricate details for more precise work on residential skyscrapers, bridges, and industrial facilities, while also avoiding expensive errors. Embracing the technology is not optional anymore; it’s a requirement to thrive in structural engineering.